Although not as rapid as electronic and ICT industry, automotive industry has been facing similar challenge during its product development. Market competition has been forcing automotive industry to squeeze its product lifecycle, release new product more frequent and also with more variants.

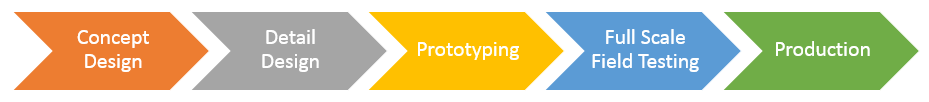

The demand for shorter product lifecycle is directly affecting Research & Development (R&D) Department of automotive industry. R&D Department must shorten the total product development phase. The shorter product development phase will require more advance development, since it has less room for repetitive problems and failures during the prototype testing.

Product development cannot afford to have repetitive failures during prototype testing. Repetitive failures will lead to delay of mass production timing, which will end up with opportunity loss. Starting mass production with an unsolved prototype testing problem, will also provide greater risk of high numbers of product recalls which lead to even greater loss.

Electrodynamic Shaker (ED Shaker) has been utilized for many years to help automotive industry to reduce the product development time. We can use ED Shaker for below tasks at different stage of product development:

Lab Scale Component Testing

Lab Scale Unit Testing

FEM Validation

Our ETS SHAKER SERIES with IPA Amplifier technology are designed to meet the requirement of various vibration test and shock test standards used by automotive industry.

With our wide range of vibration testing systems, environmental testing chambers, measurement and analysis equipment and specialized engineering services, we help customers optimize product designs and address tough engineering challenges.