The global population of Electric Vehicle have been significantly increased within the latest few years and it is forecasted that the sales of new Electric Vehicle will reach around 35% of total new car sales in 2025.

BATTERY, as one of the most CRITICAL part of electric vehicle is also having significant development period in order to fulfill the requirement from Electric Vehicle manufacturer. The testing standards and procedures are also being evaluated continuously.

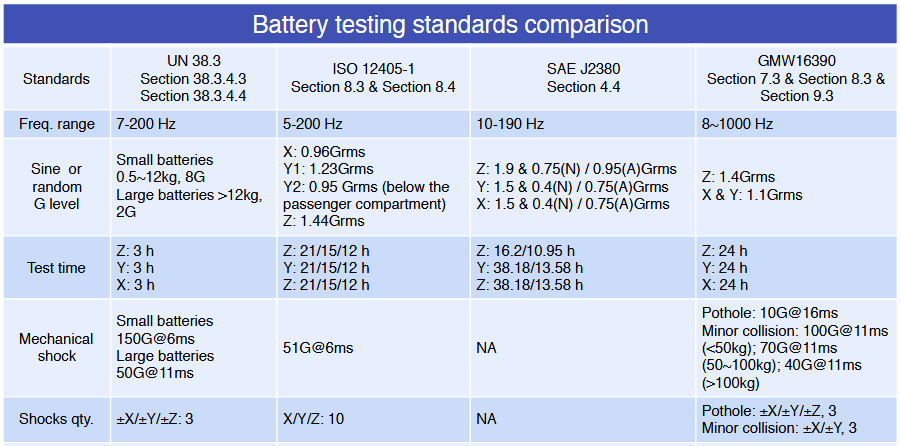

Battery need to be subjected to Vibration and Shock Testing in order to ensure the safety and robustness of the battery technology. Presently, there are three international test standard which are commonly used for Vibration and Shock Testing for Battery. They are UN 38.3, ISO 12405-1, and SA J2380. Even though, some of vehicle manufacturer have their own test standards.

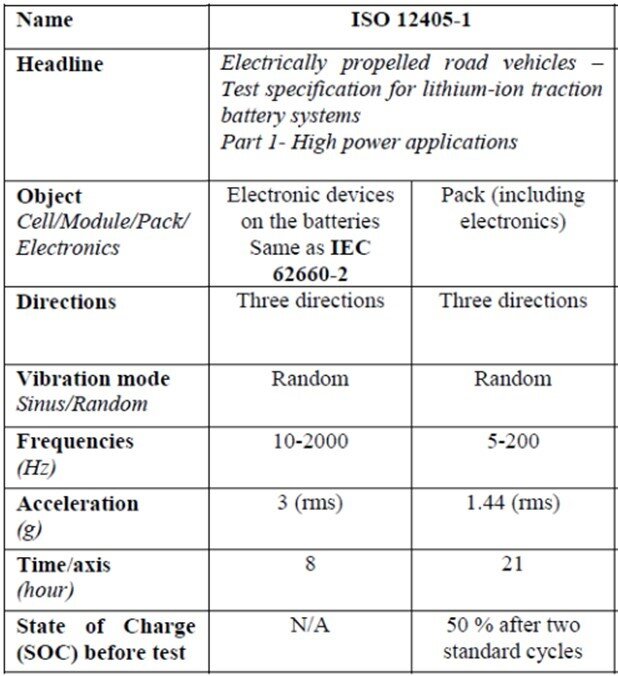

The ISO 12405 itself classifies the test sequences into two parts, the Battery System and the Electronic System.

Type of Battery product system:

Cell

Module

Pack

Entire Vehicle Battery System

ETS SHAKER SERIES with IPA Amplifier technology is designed to meet the requirement of Battery vibration and shock test standards. The Vibration Controller software has also been developed to ensure the testing accuracy.

Together with long experience in Vibration Fixture design, ETS is providing one stop solution service for Vibration and Shock Testing.

Have problems with battery testing? Please do not hesitate to contact us, we are here to help you.