The interior noise of a vehicle has a significant impact on the customer experience. Any noise outside the norm can raise concerns and discredit the company’s reputation. Engineers have a solid understanding of the noise requirements for internal combustion engine (ICE) vehicles, but electric vehicles (EV) require new standards. As EVs do not have an engine that makes noise, many normal vehicle disturbances are now audible to the passenger.

Drop Shock Testing for Products and Packaging

Many products will experience shock vibration during shipping and handling or in use. These shocks may be infrequent, such as an accidental drop or repetitive, as with transportation over rough road conditions. Vibration test engineers use shock testing to simulate these conditions in the lab and confirm the structural integrity of the device.

Software and Hardware Solutions for Simulation and Testing Engineering

ETS Solutions Asia is a leading provider of technologies, consultancy, products and services in various sectors, including industry solutions from Siemens Digital Industries Software. Specializing in Simulation & Test, we help companies establish a competitive advantage by optimizing their processes, from planning and development through manufacturing, production and support.

Types of Vibration Control

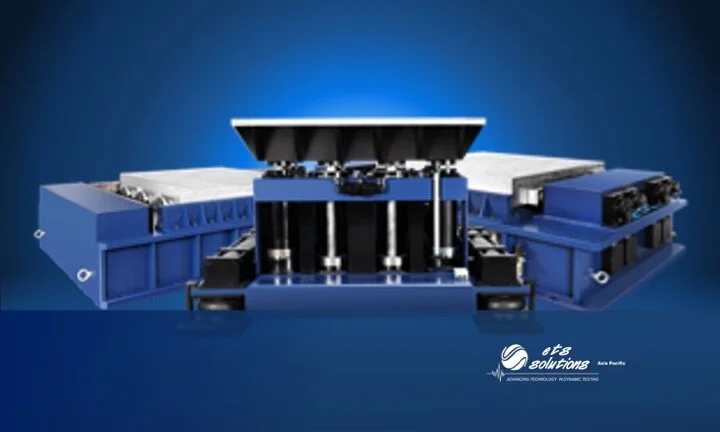

Vibration Research designs and manufactures leading edge vibration control systems for all brands of electrodynamic and servohydraulic shakers, as well as portable dynamic signal analyzers. Vibration control systems include hardware vibration controllers and the vibration control software, providing a multi-point control of complex structures, all with an intuitive user interface and easy setup.

Tips or guidance to consider before buying and operating a vibration shaker

SRS - Shock Response Spectrum

How to choose the right packaging testing methods – Shock Testing

If you’re designing the packaging for a new product or a rebranding, you probably want to know how safe your goods will be and how customers will react to your packaging before you invest in a final design. With packaging testing, you can both satisfy consumer sentiment and choose the right packaging design for your product from the safety point of view.

Batteries in Electric Vehicles, How Long Do They Last?

While it is true that electric cars lose battery capacity over time. The continuing advances in technology in precise degradation are difficult to define as a whole. The main factor is all down to the owner and how they treat the battery. The way energy is added, the way it is removed. And how many charging cycles, the battery experiences look after your battery and your battery will look after you.

Electric Vehicles Battery Testing

The global population of Electric Vehicle have been significantly increased within the latest few years. All major automakers recognize that the shift from fossil-fueled cars to EV is inevitable, and are investing accordingly. BATTERY, as one of the most CRITICAL part of electric vehicle is also having significant development period in order to fulfill the requirement from Electric Vehicle manufacturer.

Running Classical Shock Test with Electrodynamic Shaker

Shock Test, From Classical to Shock Response Spectrum (SRS)

Which type of vibration test need to be used? Should I do Sine? Why not Random? Or Shock?

Reliability is the key

The accuracy of all measuring devices degrades over time. This is typically caused by normal wear and tear. Depending on the type of the instrument and the environment in which it is being used, it may degrade very quickly or over a long period of time. Calibration improves the accuracy of the measuring device and the accurate measuring devices improve product quality.

Managing the accuracy of your measuring devices is an important job, often leading the technicians and engineers to ask “How often should I recalibrate my accelerometers, controllers or vibration meters?”

As a team of vibration test and measurement experts, we understand the frustrations of a test that results are unexpected or unreliable data, a sensor that has passed its calibration date or even worse, realizing necessary measuring devices are out for calibration.

ETS Solutions offers precise and efficient accelerometer and controller calibration, with very short turn around time, 3 days for Singapore market, bringing control and confidence to your process. We take care of your instrumentation while you focus on your own product development.

Being able to demonstrate that your equipment has been calibrated per ISO17025 standard, offers a significant payback and peace of mind, as your measuring devices are all accurate.

ETS Solutions is offering a broad frequency range from 5 Hz to 20 kHz accelerometer calibration, controller calibration, vibration meter calibration as well as data loggers calibration.