Do you have any questions on calibration services? Answers can be found in our FAQ. Calibration is to identify the accelerometer’s frequency response. Overtime the sensitivity of the sensor may drift, resulting a change in response of the sensor, in turn affecting the test accuracy. From the calibration, the data provided in the certificate can be used to calculate the overall test uncertainty.

Vibration Measurement Techniques in Power Plant

Vibration measurement is complex because of its many components: displacement, velocity, acceleration, and frequencies. Vibration measurement is an effective, non-intrusive method to monitor machine condition during start-ups, shutdowns and normal operation. Regular vibration monitoring can detect in a power plant shaft lines, deteriorations and defects of a number of various structural mechanical conditions, for example cracks, bearing faults, coupling damage, imbalance as well as interruptions in the electric grid.

Gas Turbine Vibration Monitoring

Vibration measurements are commonly considered to be a sound indicator of a machine’s overall health state (global monitoring).The general principle behind using vibration data is that when faults start to develop, the system dynamics change, which results in different vibration patterns from those observed at the healthy state of the system monitored.

Vibration Analysis on a conveyor unit

Belt conveyors are an integrated transmission and carrying mechanism with length sometimes extending several thousand meters. In traditional design and analysis of belt conveyors, vibration and impact are usually ignored and only static design is considered. However, to ensure the safety of conveyor operation for this restricted analysis, designers must increase the safety factor, which increases production costs. Many research groups have conducted dynamic analysis of large belt conveyors to reduce production cost and optimize conveyor performance. The conveyor belt was first modeled as an elastic body and then a viscoelastic body to incorporate viscoelastic characteristics of belt cover layer.

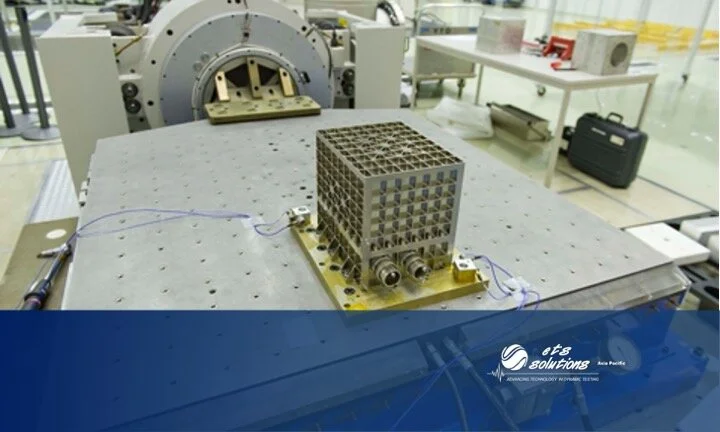

Electronic Components Reliability Testing

If your company makes planes, trains, automobiles, medical devices, computers, and communication systems, or you are a large electronic device supplier, the reliability of your products in the field is crucial to your business success. The growing market for electric and hybrid vehicles is increasing the pressure on life-time performance of the devices that power them.

Torsional Vibration Analysis

Torsional vibration measurements allow engineers to better understand the dynamics of their rotating equipment, enabling them to troubleshoot and/or validate performance. With a better understanding of the reasons and methods to measure torsional vibration, the right instrumentation, and a helpful partner, you will become better positioned to make the decisions you need to decrease downtime and increase productivity.

Vibration Analysis

Vibration analysis is the most prevalent method used to monitor the levels and patterns of vibration signals within a component, machinery or structure, in order to detect abnormal vibration events and then using that information to analyse and evaluate the overall condition of the component, machinery or structure. In short, vibration analysis helps you monitor and detect issues using vibration data

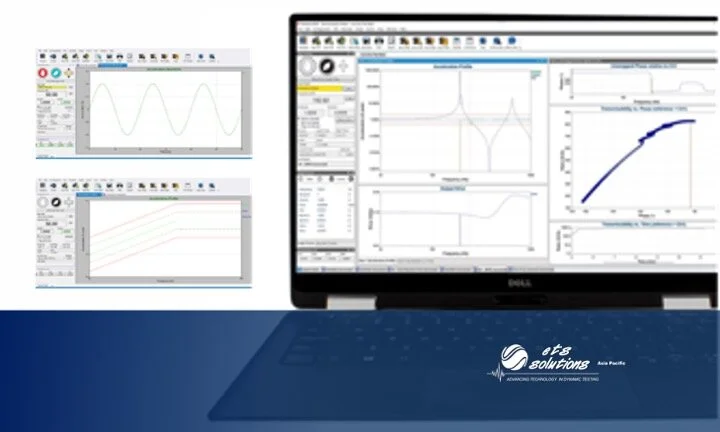

Sine Vibration Testing

Sine Vibration Testing may be considered as the most basic vibration testing method used. This type of vibration testing requires less complex parameters compare to other type of vibration testing. Knowing the nature of sinusoidal signal, makes this type of vibration testing easier to understand and to get familiar with. Though, easier to understand does not make it less important compare to other type of vibration testing. Sine vibration testing may still be at the top rank when we are thinking of dynamic characteristic measurement.

Definition of Reliability and Validity

Reliability and Validity these two terms are sometimes used interchangeably in research and evaluations. Reliability and validity are concepts used to evaluate the quality of research. They indicate how well a method, technique or test measures something. Reliability is about the consistency of a measure, and validity is about the accuracy of a measure.

Accredited Vibration Testing Services in Singapore

Products are vibration tested to determine limits and tolerances. Every product is vulnerable to vibration loads and potential breakage or failure. That includes tiny objects like microprocessors and circuit boards right up to giant structures like bridges and skyscrapers. Testing through vibrations ensures the product is qualified for its intended purpose and meets safety and regulatory standards, as well as complies with any International Standards Organization (ISO) requirements.

Addressing complex engineering challenges by enhancing simulation efficiency

Computer-aided engineering (CAE) has long proven its value as a troubleshooting and analysis tool, but is generally perceived as slow, delivering accurate results too late to drive development. The simulation process with traditional CAE tools is slow due to tedious geometry cleanup processes, and simulation disciplines are disconnected from each other, hampering efficient workflows.

Calibration of Vibration Controller

To run a vibration testing, we need to set our test specification at the vibration control software and let the vibration controller to control the rest. A feedback sensor will send feedback signal. And based on this feedback signal, vibration controller will adjust the drive signal to make the actual vibration signal aligned with the test specification. Looking at how this system works, it is clear that the vibration controller is playing a very important part to accuracy of the vibration testing.