Vibration measurements are commonly considered to be a sound indicator of a machine’s overall health state (global monitoring).The general principle behind using vibration data is that when faults start to develop, the system dynamics change, which results in different vibration patterns from those observed at the healthy state of the system monitored.

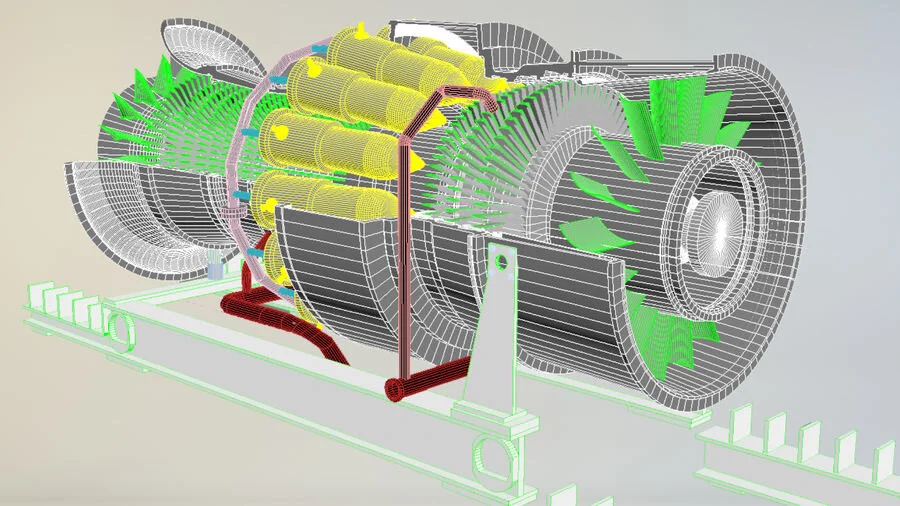

In the industry, several types of gas turbines are used, for example in gas transportation, chemical processes, electricity generation, the aerospace industry and other applications. Understanding the vibratory behavior of a turbine is an industrial challenge that has continued to increase in importance in these industrial sectors.

Uncontrolled dynamic deformation of the structures of the bearings and fins of a turbine can lead to premature aging of these components or to unacceptable noise and vibratory nuisances with non-linearity's present in the turbine system which are of different natures: combustion instabilities, such as the air / gas ratio which is responsible for the emission of nitrogen dioxide in large quantities and the instabilities related to the aero elasticity; Floating which begins with the natural frequency of the blade of the rotor with aerodynamic instabilities. This instability can cause deterioration of this machine, so it is essential to keep gas turbine operation outside of the instability zone.

Potential failures have different distribution depending on the application (mechanical design, operation range, environment etc.). Investigations show that around 70% of all failures can be assigned to product faults such as:

Material faults (e.g. due to fatigue or off design)

Faults in planning

Manufacturing faults

Assembly and repair

To prevent this phenomenon, in recent years, gas turbine manufacturers have turned their attention into increasing the reliability and availability of their fleet, using data-driven vibration-based condition monitoring approaches to continuously monitor the mode of operation of these machines.

These methods are generally preferred, for online monitoring strategies, over a physics-based modeling approach, where a generic theoretical model is developed and in which several assumptions surround its development. In the case of data-driven condition monitoring approaches, a model based on turbine data can be constructed so that inherent linear and non-linear relationships, depending on the method, that are specific to the system being monitored, can be captured. For this reason, manufacturers see the need to implement such approaches during pass-off tests, where it is necessary to identify possible defects at an early stage, before complete component failure occurs.

The advantages of running a condition and predictive maintenance of a gas turbine are:

Higher production output

Less unexpected repairs

Optimized maintenance scheduling

Optimized machine performance

It is known that industrial sectors are a challenging environment in maintenance terms, in which the availability of assets is of the utmost importance. A considerable number of essential rotating machines, structures and piping networks are subject to high levels of demand, and staff turnover levels are also high.

With ONEPROD condition-based maintenance solutions, it is possible to avoid production downtime resulting from unexpected failure, and to ensure better management of spare parts (compressors, water injection pumps, etc.). The ONEPROD innovative solutions make it possible to:

Easily monitor inaccessible machines in explosive areas, using EAGLE wireless sensors,

Keep qualified personnel offshore at all times, with FALCON’s automatic diagnosis capabilities,

Make vibration measurement accessible to anyone, thanks to FALCON’s smart user guidance,

Easily access assistance whenever and wherever you need it (troubleshooting, training, remote assistance capabilities, etc.).

Interested in more insights and best practices like this? Sign up to get the best industry insights, tips, and trends from ETS Solutions Asia in your inbox each week!