Shock and vibration resistance gives information concerning the robustness of the mechanical design of a device. The methods for evaluating the vibration resistance are defined in IEC 60068-2-6 and IEC 60068- 2-64. Electrical and electronic equipment are exposed to vibration in many applications and must withstand this without any degeneration, or even failure, in their function. Therefore, manufacturers of electrical and electronic devices put a great deal of effort into ensuring their instruments are prepared for such applications.

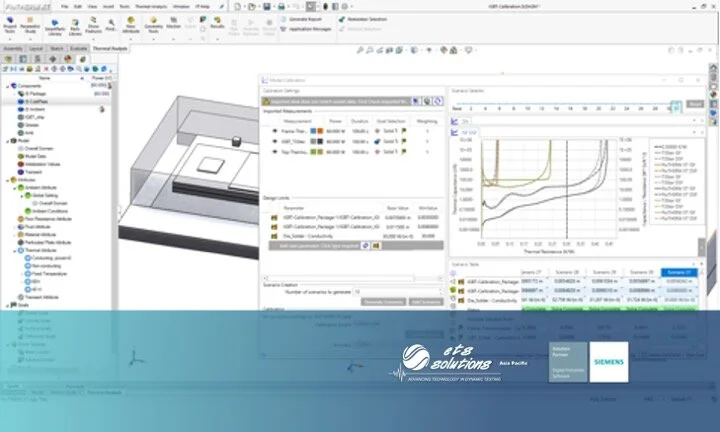

Automatic Thermal Model Calibration

What are transient thermal measurements and structure functions, their advantages, and how we use them tcalibrate and improve our semiconductor thermal models, Simcenter Flotherm is a unique combined test and simulation solution for automatic calibration of semiconductor package thermal models that maximizes simulation accuracy. This helps engineers to better optimize electronics thermal design for reliability, reducing field failures, and to reduce overdesign-linked costs.

Random Vibration Testing

Different Types of Calibration

Measurement equipment calibration can be carried out on different types of instruments across different sectors. Electrical calibration refers to the process of verifying the performance of any instrument that measures or tests electrical parameters such as: voltage, current, resistance, inductance, capacitance, time and frequency. Mechanical instruments are subject to drift due to regular usage, mechanical shock and exposure to varying atmospheric conditions, as such mechanical calibration is needed.

The benefits of An Accredited Calibration Services Laboratory

The benefits of calibration include improving safety as well as saving money and increasing profitability by avoiding the costs of false acceptance and rejection of products, increasing production efficiency, and extending the life of the equipment. Since the standards of accredited calibration labs are set really high, you can be confident of the accuracy levels of the calibrations.

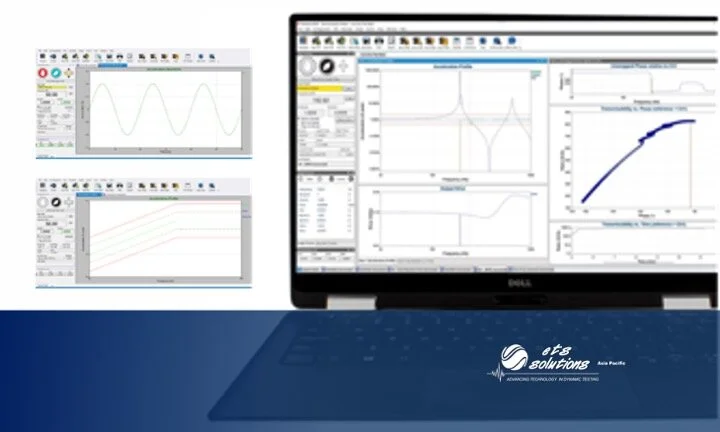

Sine Vibration Testing

Sine Vibration Testing may be considered as the most basic vibration testing method used. This type of vibration testing requires less complex parameters compare to other type of vibration testing. Knowing the nature of sinusoidal signal, makes this type of vibration testing easier to understand and to get familiar with. Though, easier to understand does not make it less important compare to other type of vibration testing. Sine vibration testing may still be at the top rank when we are thinking of dynamic characteristic measurement.

Factors That Affect The Accuracy of Measurements

Instrument calibration ensures that the instruments perform with high accuracy without compromising the final quality of the product. They perform best when they are calibrated following the manufacturers’ recommendations. Several factors may affect calibration, which will further affect the end quality, rendering the objective of calibration useless. Three of these factors are discussed in this article.

Calibration Programs Can Improve Your Business

Structural Dynamics Testing Made Easy with Simcenter

Simcenter solutions offer an integrated approach to test preparation, modal testing, modal analysis, numerical model correlation, model updating, and model use. from impact testing on small structures to large scale campaigns using hundreds of measurement channels, puts a tradition of cutting-edge expertise at your fingertips as you maximize testing efficiency.

We Wish You a Happy Merry Christmas

Definition of Reliability and Validity

Reliability and Validity these two terms are sometimes used interchangeably in research and evaluations. Reliability and validity are concepts used to evaluate the quality of research. They indicate how well a method, technique or test measures something. Reliability is about the consistency of a measure, and validity is about the accuracy of a measure.

Simcenter Help Facebook to significantly improve its new server design and achieve thermal efficiency

For its first datacenter in Prineville, Oregon, Facebook set out to significantly improve its power efficiency, cost, reliability, serviceability and environmental footprint. To this end, a holistic approach was used to redesign many dimensions of the datacenter and servers. This white paper1 focuses on the Facebook server design, combining aspects of power, motherboard, thermal and mechanical design.

Is your electronics cooling software fit for purpose?

More than just a CFD code, STAR-CCM+ is a complete multiphysics toolbox, able to solve flow, thermal and stress problems involving multiple phases. From liquid jets, to water ingression, STAR-CCM+ allows you to simulate any cooling strategy that you can define and even the effect of what happens when those strategies go wrong.

Limitations of Existing Vibration Testing Systems

Running Test with Shock Test Machine

Finding the longest lasting design faster

The first is a hybrid approach, integrating test and simulation for realistic road-load prediction, even for loads that cannot be measured. And the second is a digital road approach, running a comprehensive virtual model on a digital track when test data is unavailable. Additionally, it considers new emerging technologies, such as composites and additive manufacturing.

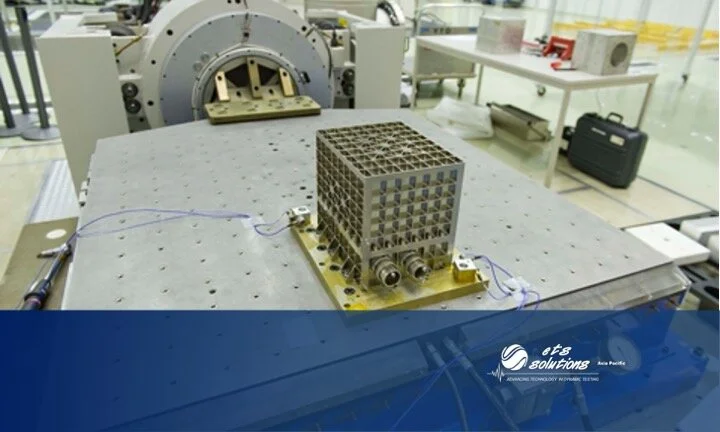

MIL-STD-810 Standard - Various types of vibration tests

ETS I Series Vibration Testing System with force rating from 4,000 to 16,000 kgf is ideal for screening of medium sized assemblies with extreme high acceleration test level and high frequency range. The Extreme Acceleration Shaker Y-Ring (EAS-Y Ring) armature is a revolutionary design which will allow for using a proportioned head expander to test multiple specimens simultaneously at extreme high acceleration level.

Accredited Vibration Testing Services in Singapore

Products are vibration tested to determine limits and tolerances. Every product is vulnerable to vibration loads and potential breakage or failure. That includes tiny objects like microprocessors and circuit boards right up to giant structures like bridges and skyscrapers. Testing through vibrations ensures the product is qualified for its intended purpose and meets safety and regulatory standards, as well as complies with any International Standards Organization (ISO) requirements.

Simcenter road load data acquisition solution

Providing safe and efficient vibration qualification testing

For your vibration qualification tests, the unique combination of Simcenter SCADAS™ hardware, Simcenter Testlab™ software and ETS Solutions expertise in vibration testing, delivers outstanding performance for all standard and advanced testing requirements. This includes tests based on tailored profiles, interfaces with test cells or climatic chambers, and tests based on newer techniques such as the military standard (MIL-STD) 527 method.