Additive manufacturing (AM) is changing the way products are made. New revolutionary machines and processes are rapidly pushing AM from the prototype environment onto the production floor. The additive manufacturing capabilities in Simcenter 3D software are used to predict distortions and defects before parts are printed, thereby reducing the number of test prints and improving the quality of the final print.

High-quality simulation environment

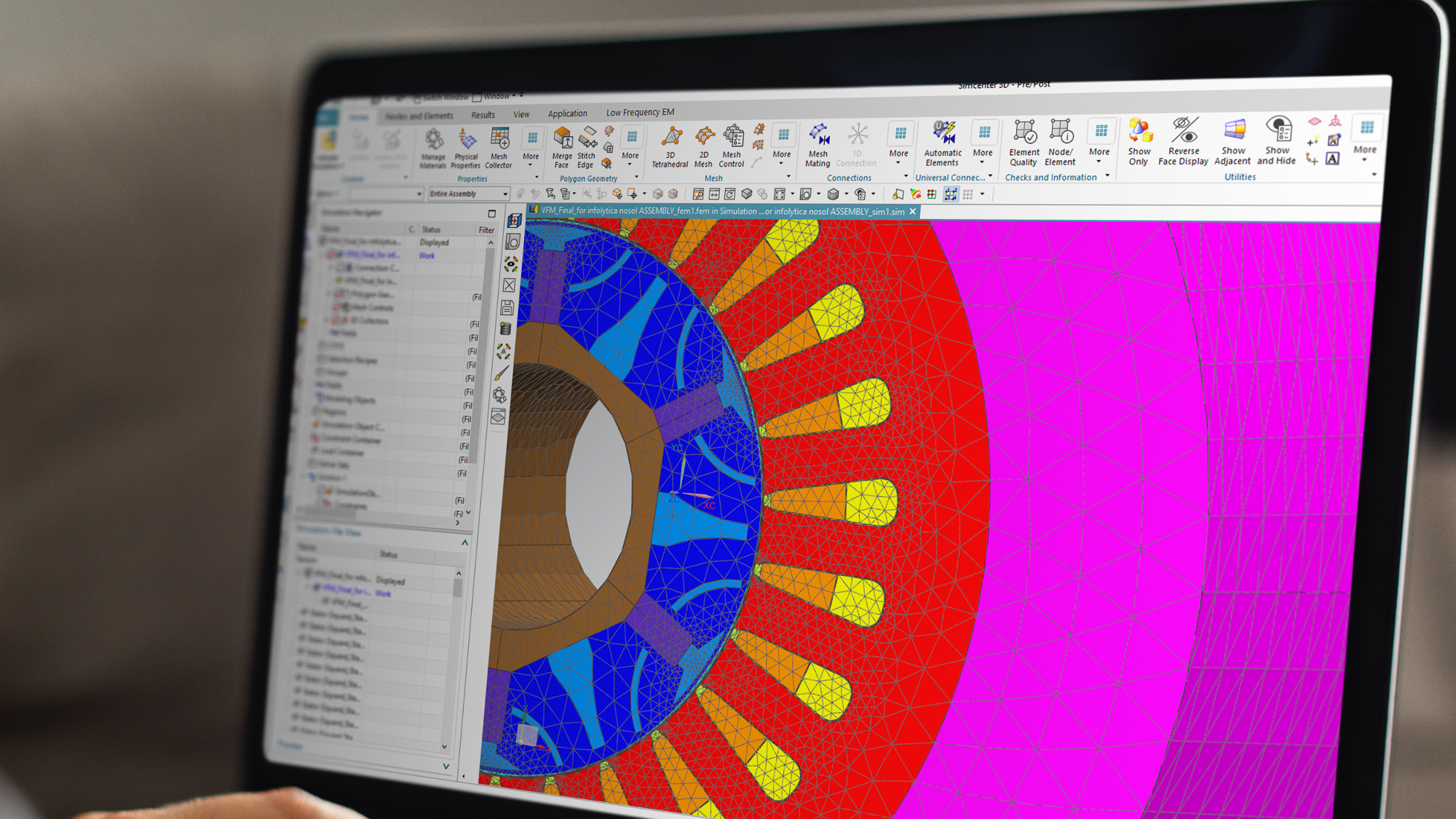

The high-quality simulation capabilities of Simcenter 3D are paramount to industrializing AM. During the AM process simulation, the parts are meshed accurately with tetrahedron meshes and sliced afterward, which gives better results than voxel meshes.

Enhanced inherent strain approach

A new approach was developed that was brought to the market with Simcenter 3D. The layer-by-layer build process during the powder bed fusion printing leads to layer shrinkage during the cool down of the layer. The stiffness of the printed structure has a strong influence on part distortion.

Print right the first time

Calculated distortions can be used to compensate for the part prior to the printing process. The initial geometry can be automatically morphed into the precompensated shape and replaced in the built tray for further analysis, or it can be sent directly to the printer to be printed correctly the first time.

Fully integrated with NX end-to-end workflow

Simcenter 3D for AM is seamlessly integrated into the end-to-end Siemens’ digital enterprise software AM workflow. The process is streamlined to be used by nonexpert computer-aided engineering (CAE) users as well.

Providing a platform for multidiscipline simulation

The Simcenter 3D AM solution is part of a larger, integrated multidiscipline simulation environment with Simcenter 3D Engineering Desktop at the core for centralized pre-/postprocessing for all Simcenter 3D solutions. This integrated environment helps you to achieve faster CAE processes and streamline multidisciplinary simulations that integrate additive manufacturing with any of the Simcenter 3D solutions, such as thermal mechanical, vibro-acoustic, or other more complex analyses.

Solution benefits

Print right the first time

Simulate the build process for metal powder bed fusion additive manufacturing applications

Predict potential geometry distortions during the build

Investigate efficiently different build positions and support scenarios

Mesh the specimen geometry exactly using powerful Simcenter 3D algorithms

Generate compensated geometry (BREP) based on the simulated distortion fields

Industry applications

Today, AM is still mainly a research and development (R&D) activity as this process remains expensive and slow, preventing its use for large projects such as in the automotive industry.

However, some industrial applications are already linked to the printing of complex parts, which are difficult to produce by traditional methods.

The primary goal is to create parts that are lightweight and have good mechanical properties.

Repairing parts previously produced by traditional processes can also be a valuable application of AM due to the unique nature of each component.

Aerospace and Defense

The space industry already produces structural parts for launchers. The goal is to produce parts that are light-weight and have good mechanical properties.

The airplane industry is also developing this technology, but is in more of an exploratory phase with the goal of producing components with complex geometry.

Industrial machinery

Power generation appears to be an industry that is exploring AM to produce turbine blades and other combustion chamber components. AM can also be applied to repairing existing turbines.

Automotive industry

Lightweight structures for racing cars and completely new bionic designs can be manufactured with additive manufacturing technology. Generative design can be used to find new proposals that can be manufactured with additive manufacturing technology.

Simcenter 3D Additive Manufacturing simulates the AM process for selective laser melting (SLM).

The setup from a part in the built tray, including support structures, is used as a basis. The user selects the parts to simulate and define printing process parameters (mate- rial, number of parts, layer slicing, laser parameters, etc.) and run the simulation. The result is the temperature distribution and distortion of the part.

Module benefits

Simulation of the build process for powder bed fusion metal prints

Fully integrated in to the NX software additive manufacturing framework

Unique model setup and solving methodology

Key features

Solving the coupled thermomechanical solution

Material and process parameters for AM

Consideration of support structures from fixed plane modules

Analyze thermal distribution

Analyze distortion before and after support removal

Predict probability of overheating

Efficiently compute stiffness curves

Compute pre-distorted geometry for compensation