Ideally, the vibration test fixture should be designed to be:

As light as possible

As stiff as possible

But in the real vibration testing world, there are a lot of constraint that we need to consider and then we need to find and optimum point, that can balance all required aspects such as cost, timeline, etc.

Below are some practical aspects that we may need to consider during the design process of our vibration fixture:

Material

Traditionally, aluminium and magnesium are used commonly for vibration test fixture. Magnesium may have more suitable mechanical properties for vibration testing purpose. It is lighter than aluminium and has better damping properties. Even though, aluminium may still be the favourite material for vibration testing purpose. It may not be as light as magnesium, and the damping properties may not be as high as magnesium, but aluminium may be more available and easier to get.

Standard type of aluminium may also be more cost effective in terms of raw material cost. Steel is not considered as common material used for vibration test fixture. Due to its high density, the final fixture weight may become 3 times of aluminium based fixture. Another reason why steel has not been favourite type of material for vibration test fixture is due to its light damping properties. In some cases, we may want to think of combining common vibration testing fixture material like aluminium or magnesium with polymer material such as nylon, polypropylene (PP), polycarbonate (PC), etc. Polymer material may not be suitable for vibration testing due to its low stiffness.

But there are some cases (example: automotive component testing) where we want to represent the actual condition as much as possible, then we may need to use polymer material, especially at the UUT mounting areas. In this type of case, we may still need to ensure that the fixture vibration characteristic is within acceptable level. But if the UUT size is quite small and light (example: small sensor or electronic component), then we may also think of completely using polymer material, especially if we have vibration shaker with very limited force capacity.

Weight and Size

The weight and size of the fixture are important factor that we will need to pay attention. The heavier is our vibration test fixture then the acceleration we can achieve during the test will be getting lower. For Sine testing or Random testing, it may not be an issue since normally Sine testing or Random testing will not require high acceleration level of testing. But for Shock testing, there are many cases that we are required to run high shock acceleration level of testing at long pulse duration (example: 11 ms).

For this type of cases, if we want to run shock test with vibration shaker then we will need vibration shaker with high force capacity. And this is the type of case that we really want to squeeze the weight of our vibration test fixture to be as light as possible. But sometimes, when the size of our UUT (Unit Under Test) is quite large, then it becomes very difficult to avoid this.

Center of Gravity

Basically, we would want to make the center of gravity of the vibration test fixture plus UUT to be at the center as possible, aligned with the thrust axis of the vibration shaker. We also would want to have the center of gravity of vibration test fixture plus UUT to be as low as possible, as close as possible to armature. By having this, we reduce the bending moment which will create extra load to vibration shaker, which may provide extra life to our vibration shaker component. Other than this, keeping the bending moment to be as low as possible will also make easier to vibration controller to control the running test.

There are some cases, when we want to run high acceleration shock test, with low number of pulses, vibration controller may need more time (pulses) to make the test result stable due to the existence of this extra bending moment. In some cases, we will need to set the shock level gradually before reaching the target level. But we may also need to pay attention that increasing shock level gradually means we are adding in extra pulse which means extra damage event to our UUT (over-testing).

Resonance

Resonance of our vibration testing fixture may be considered as one of the most important aspect that we need to pay attention during the fixture design process. Basically, we would want to push the fixture resonance out from the test frequency range, as far as possible, as high as possible. Having resonance within our test frequency range may lead the UUT becoming undertested or over-tested.

When the UUT is over-tested and failed during test, it will not be easy to justify if the failure is due to UUT's lack of quality, or due to the fixture that is amplifying the vibration fatigue damage. In the case of small UUT, keeping the test frequency range free from fixture's resonance may not be difficult task. But when we are dealing with bigger UUT, then shifting out the fixture's resonance out from test frequency range may become challenging. Rather than running physical trial and error, we may consider using Finite Element Simulation to run virtual testing, to estimate the fixture's resonance frequencies.

Structure

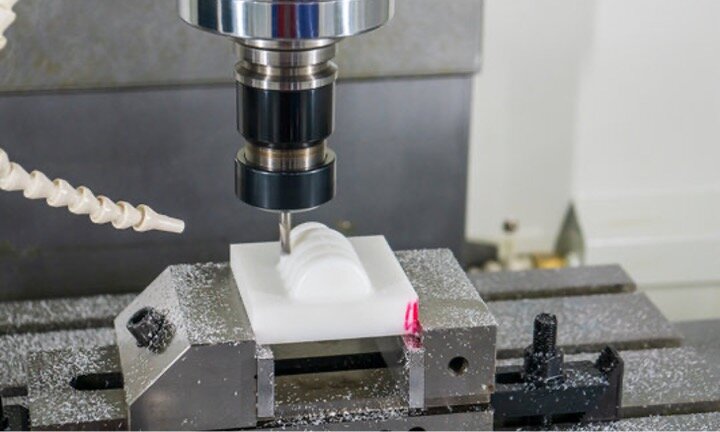

During the vibration test fixture design process, we may be dealing also with options, if we want to make the fixture as one piece of metal, or multiple pieces of metal. Having the vibration testing fixture as one piece of metal will make the engineer's life easier. From the fixture designer point of view, during the Finite Element Simulation process, having one piece of metal will remove one of the biggest problems of Finite Element Simulation, which is non-linear boundary condition.

Having one piece of metal will reduce the modelling error due to non-linear friction between metal plates. From the test engineer point of view, having vibration testing fixture as one piece of metal means we remove one issue related to manufacturing tolerance. From the other perspective, vibration test fixture as one piece of material means less cost effective since it should normally undergo machining process by using CNC machine. Some manufacturers already developed additive manufacturing method (3D Printing) using metal-based material. But so far, how to make the final mechanical properties produced suitable for vibration testing is still under research and development. Using 3D Printing to fabricate only low number unit of vibration test fixture may not be cost effective as well.

Other than having the fixture as one piece of metal, the other options we have are having multiple plates with welded joints or screw joints. From fixture stiffness point of view, having continuous welded joint along the line may produce better stiffness compare to screw joints. But from other points of view, maintaining dimensional accuracy of the fixture during welding process may not be easy due to thermal deformation. To produce welding joints on aluminium material may also not be as simple as welding for steel material. For these reasons, some designers prefer to use screw joints.

Assembling

During the vibration test fixture design process, in some cases, we may want to pay attention also on how the UUT is going to be assembled into the fixture, especially when there are many mounting points available. When there are mounting screw that have different mounting direction, we may want to pay attention to the assembling sequence. In some cases, for a complex vibration testing fixture, some component of fixture may need to be mounted after the UUT.

For this type of cases, we may need to ensure that we have enough space and clearance placing the UUT on the vibration test fixture. Another aspect that we may need to pay attention is the space for our tool needed for assembling. We have to ensure that there is enough space for the tools (example: screwdriver, allen key, spanner, etc) to access the mounting areas.