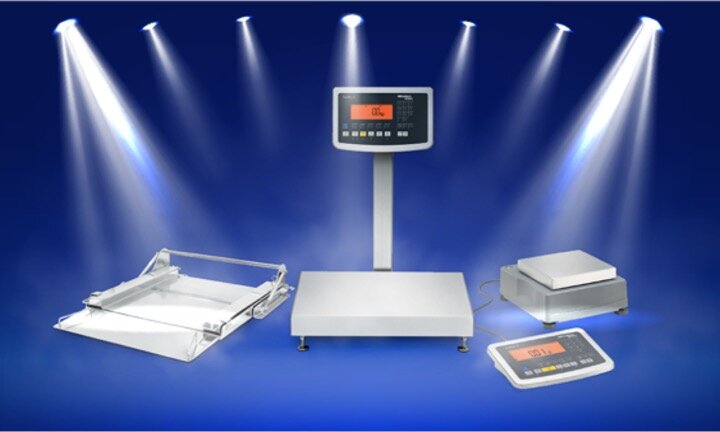

Industrial floor scales are characterised by extremely large platforms and are suitable for all sectors in which heavy and bulky loads have to be weighed. In the shape of the floor scales Combics® and Midrics®, along with the flat-bed scale IF and the pallet scale IU, Minebea Intec offers a raft of weighing solutions – including for potentially explosive environments.

Flat-bed scale IF

The flat-bed scale IF has been developed for the maximum possible ground-level use in the smallest possible space. It is a high-quality, flexible and mobile weighing station, which can be used anywhere in the production process where reliable measurements and hygienic solutions are required.

Its benefits and options are:

Custom specifications available on request

A variety of finishes, e.g. stainless steel

Verification mode and explosion-proof solutions

IP65, IP68 or IP69 protection classes

Resolution up to 30,000 d and up to 2 x 3,000 e

in situations where verification is required

Load ranges of between 150 kg and 3,000 kg

Platforms in various designs and sizes

Why a flat-bed scale from Minebea Intec?

Ergonomic design for easy handling

Hygienic Design, e.g. for use in clean rooms

Tough and robust for use with aggressive substances

Easy dry and wet cleaning

Rollers and steering drawbar for mobility

Reliable construction guaranteeing low maintenance costs and a long service life

Various designs and options for customised solutions

Standard flat-bed scale IF

Low platform height and very short ramp with minimal incline to save on space. Available with drive-through protection, additional transport handles and rollers, among other options.

Flat-bed scale IF with pneumatic lift mechanism

Ideal for stationary use. For complete cleaning of the scale and floor, the platform is just folded up. Available with a second ramp or as a weighing solution for operation by one person, among other options.

Flat-bed scale IF with rollers

The version with retractable rollers can be pushed by one person, making it ideal for use in a number of different locations and for easy floor cleaning. Available with retractable rollers or steering drawbar and drive-through protection, among other options.

How to choose the right industrial floor scale

Industrial scales contribute heavily to the process chain. In view of the wide range of scales, it is important to find a tailored solution for highly technological processes that seamlessly integrates into the existing production process. Seeking this solution involves both requirements on the equipment, such as the weighing range, the resolution or the repeatability of results, and also the physical characteristics, such as the material constituting the build of the scale. External factors such as outside interference or process requirements also place additional requirements on an industrial scale. So that the scale can communicate continuously with the other equipment, selecting the appropriate interface is also essential.

Selecting the perfect scale provides several advantages for the user, such as:

Increased efficiency

Intuitive operation prevents errors in use

Minimising rejects

Reliable sample weighing

Saving time and cost when cleaning thanks to the hygienic design

One of the first steps in the selection process should be to determine which tasks the scale is intended to fulfill within the production process. Generally, the scale, a measuring instrument, is integrated into the production process at a specific point where it is intended to fulfill a certain purpose. The primary use of a scale is to weigh things. For this purpose, an appropriate vessel or a moveable container is placed or driven onto the scale, the scale is tared and the solid or liquid sample is placed into the vessel or container according to the specifications. The weight is recorded manually or electronically and the sample, along with the container, is removed from the weighing pan on the scale.

Areas of application of an industrial scale

Industrial scales can be integrated at almost any point in the production process. Amongst others, the areas of application of an industrial scale are:

Check weighing and integrity checking

Classification, sorting and counting according to weight

Batching and formulation in recipe management

Checking ingredients, production quantities or goods issue

Order picking for shipping

Statistical control of production processes

The Scale’s Size and Capacity

A scale’s capacity indicates the maximum quantity or mass that a scale can weigh. As a rule, stand and floor scales are used for up to around 150 kg; and floor scales only are intended for weighing items of 300 kg and more.

Always keep in mind that the weighing capacity of the scale should be within the middle range. This not only prevents unnecessary stress or damage to the sensitive electronic components, but also ensures higher accuracy. High-quality scales have a built-in overload protection in case the scale is overloaded or objects inadvertently drop on the weighing platform. This prevents, by physical means, the electronics and metrological components from suffering permanent damage.

In terms of capacity, the load area on the scale is always one of the factors to be considered when selecting a scale. It is important that the container or the sample can be optimally placed within the scale’s weighing area. Ideally, the sample should be centered on the platform and not hang out over any sides. To ensure this, scales are supplied in a wide variety of platform shapes and sizes for the various purposes. This also applies to large tanks or silos with load cells built into the base frame. What are called under-balance or below-balance methods exist for situations where it is difficult or impractical to weigh directly on the platform. In these cases, a hook attached under the scale is used to measure the weight by means of tension.

The Required Weighing Accuracy

A quantifiable characteristic of measurement – accuracy – has always resurfaced as a subject of heated debate in the entire weighing industry for the reason that no exactly specified definition exists. In actual fact, accuracy can be regarded as an interplay of many different factors; four quantifiable specifications in particular, contribute to this interplay:

Resolution

Reproducibility

Linearity

Uncertainty of measurement

Resolution, also referred to as readability, is defined as the smallest change in mass that can still be read on a particular scale regardless of its weighing capacity. Let’s take a sample, say, that weighs 114.318 kg. If we weigh this sample on one scale with a resolution of 0.001 kg, it reads 114.318 kg; another scale with a resolution of 0.01 kg will read 114.32 kg.

Reproducibility is defined as a scale’s ability to display consistent results over a certain period of time and when operated by different users. To determine a scale’s reproducibility, a test weight is weighed ten times. Then, these ten measurements are used to calculate the standard deviation, which is equivalent to the scale’s reproducibility. The calculation can be carried out manually, although many high-quality scales perform this task automatically.

Linearity is defined as a measurement of a scale’s deviation (variance) in accuracy across all weight values within its capacity, including maximum weight values and values in the mid-capacity range. A linearity test is part of the annual calibrations performed by quality scale manufacturers and approved customer service centers within the scope of their services.

Linearity errors can affect the accuracy of measurements

Uncertainty of measurement is defined as the difference between the measured weight of a certain sample compared to its true weight. Deviations can arise due to the weighing environment and additional factors. In certain applications, the uncertainty of measurement is monitored closely. For example, Chapter 41 of the U.S. Pharmacopeia (USP) specifies that the uncertainty of measurement during sample weighing may not exceed 0.1% of the quantity to be weighed. Laboratories that rely on scales generally comply with this guideline, which is also gaining acceptance in production applications (production scales).

The Scale’s Environment

Selecting the Materials of Construction

In simple terms: scales can be classified into two general categories: basic scales and scales subject to high environmental demands. Basic scales are made of normal materials that may include plastic, coated aluminum alloy, painted or galvanized carbon steel. Usually, these scales are used for weighing processes in areas like logistics or warehouse weighing where the ambient conditions are dry and hygiene and corrosion resistance are not critical factors. The temperatures can vary around room temperature, but can also range significantly above (summer) or below (winter); humidity levels may also be subject to great fluctuations.

In environments that require a higher level of cleanability/hygiene or chemical compatibility and environmental stability, stainless-steels of the AISI-304 and AISI-316 grades are the most commonly used materials. Also referred to as austenitic stainlesssteels, their resistance to corrosion and oxidation is ensured by a passive layer on the metal surface (metal oxide or metal hydroxide) that is only a few Angstrom units thick, but sufficiently protects the metal from any otherwise corrosive substances (from the working environment or from the sample itself).

In the food and beverage, the cosmetic, paint and pigment industries and in sectors that work with large amounts of chemicals, the stainless-steels of the AISI-304 grade have proven their merits. This material is not only resistant to chemicals in the product itself, but also to the chemical agents contained in cleaning agents; nevertheless, this steel will tarnish in the presence of extremely aggressive chemicals.

If better protection is needed, grade AISI 316F stainless-steel is a more suitable material of construction. Because it contains a higher nickel content and up to 3% added molybdenum, this material has a markedly improved resistance to the pitting corrosion caused by aggressive chemicals like chlorides, salts and acids. If even further protection is required, AISI 316 stainlesssteel is available in various sub-grades, including grade 316 L, which has a lower carbon content for better corrosion resistance, while 316 Ti has added titanium that gives this grade greater tensile strength and improved resistance against inter-crystalline corrosion.

To ensure that the strictest requirements for corrosion resistance and hygiene are met, for example in pharmaceuticals and medical technology manufacturing processes, the AISI 304 or 316 grade stainless-steels must be electropolished. Electropolishing decreases the surface roughness of the metal down to such magnitudes that bacteria cannot adhere to it. During electropolishing, an anodic workpiece made of stainless-steel is immersed in an electrolytic bath and connected to the positive pole of a current generator. The negative pole is connected to the cathode. When an electrical current is connected, the particles move away from the anodic stainless-steel workpiece to the cathode. This causes the surface roughness of the workpiece to decrease and the concentration of chromium in its surface to increase. The surface thereby created has a very low roughness which improves corrosion resistance and reduces microbiological contamination. The current standard is a roughness <1μm; however, <0.8µm and <0.4µm is even better in qualitative terms.

External Impact Factors

The ambient conditions prevailing at the place of installation are selection considerations that are often overlooked. Every scale is a measuring instrument that has a task to fulfill, namely to determine a weight value, while at the same time being subject to physical effects from the environment. Although each scale is designed to operate within a certain temperature range, it is still preferable to keep the temperature of the ambient air steady. Extreme fluctuations in temperature can cause metals within the load cell to heat up and flex at different rates. As a result, during the phase of temperature fluctuations, the weighing results can also fluctuate. Whenever the temperature in the scale’s environment fluctuates, the scale should be allowed to acclimate to the new temperature prior to first use. Modern scales are built to compensate electronically for the external impact of temperature.

If the sample exhibits temperature extremes, heat or cold can be conducted to the load cell where the fluctuations described can take place in the same way. In such cases, ceramic or temperature resistant pads can be used to prevent direct contact between sample and load cell. Even air currents can affect the performance of higher-resolution scales. A draft shield can be attached for such cases to reduce or eliminate the air currents (for example next to rolling gates). The presence of magnetic fields and floor vibrations can also negatively affect a scale’s performance at higher resolutions.

Nevertheless, although on scales with lower-resolution these effects are less problematic, appropriate measures should be taken to protect the scale. Specialized vibration-isolating padding can help, or usually, the easiest solution is simply to move the scale to a more favorable location. To a certain extent, most scales are resistant to humidity and fluids, since many branches of the industry rely on wash-down methods during cleaning. Nevertheless, their resistance to destructive chemicals or deposits should be monitored carefully. As required, the appropriate corrective actions should be taken or a more suitable scale model should be selected (e.g., scales with special protection devices).

Process Requirements

In addition to the performance characteristics mentioned in the previous section, scales can be customized with additional features. For example, wheels or special lifting mechanisms can facilitate thorough cleaning in the area under the weighing platform. Drive-on ramps, pit-frames or flat-bed scales make it easier to load and unload large or heavy items. In addition to scale-specific calibration routines, integrated software options can include pre-programmed or programmable application programs. Modern scales can optionally be connected to a PC or a network via Bluetooth, RS232, RS485, TCP/IP, Ethernet, Profibus or other porting devices.

For scales used in production processes or for remote-controlled operation, the weighing results can be display at locations remote from the weighing platform at control centers. If the scale is set up in a poorly lit area, a backlit display can effectively eliminate any problems with readouts, while a range of 3-key scales to scales with alphanumeric keypads ensure simple operation. Graphic displays can generate curves or bar diagrams to provide the user with added information. This feature is especially helpful for illustrating statistical variables, such as bar diagrams or time curves of measurements. Moreover, modern scales can display and print out measured values in several different languages and in multiple weight units.

In summary, it is important not only to identify the process-related features that are highly relevant to current process requirements, but also the needs to be expected in the future (for example, data collection for all production parameters).

Regulations and Rule Books

Numerous industries are subject to specific regulatory criteria that the weighing instruments employed must or at least should comply with. The regulations and standards listed in the following are intended to give you an overview about the guidelines applicable to certain industries. In this connection, it is highly recommended to thoroughly review regulations specific to the branch of industry.

The requirements of the ECEx, NEC (USA), CEC (Canada) and the European Union in the area of ATEX explosion protection (ATEX stands for the French term: Atmospheres Explosibles) ensure the safety of electrical equipment used in potentially explosive areas. The equipment is tested and certified in accordance with the standards of various organisations such as ATEX, the American National Standards Institute (ANSI), FM, CSA and the International Electrotechnical Commission (IEC). Under the ATEX directive, in addition to certification by an appointed body, assessment by the manufacturer is also permissible.

In addition to equipment approval, regular monitoring of quality assurance by an appointed body or, for the FM and CSA, by the organisation that issued the approval is also required.

Originally established for the food industry, the seven principles behind the “Hazard Analysis and Critical Control Points (HACCP)” concept are increasingly being used in the pharmaceutical and other industries as well. Even though the HACCP principles are supervised by a regulatory body, these self-regulating criteria stress the importance of hazard detection and prevention in a process. This way, process risks can be minimized. It’s not necessary to go into further detail about the corrective actions required in the event of failure and the repercussions that come in their wake. Every responsible manufacturer understands the costs and long-term risks for his company.

The IEC is a system for classifying electrical equipment safety based on definitions according to IP codes (IP = Ingress Protection). The higher the protection rating, the better [the electrical equipment is protected against dust, foreign particles and moisture (this extends to water jets). Although the commission does not certify equipment, the standards can be self-certified. Moreover, external testing institutes can also issue the appropriate certificates.

The International Organization for Standardization, abbreviated ISO after the Greek word isos for “equal”, is the standards organization that arguably enjoys the greatest recognition worldwide. This non-governmental agency develops a broad range of technical standards throughout the world which are valid for a number of industries and markets. Neutral testing organizations conduct conformity assessments and approvals. Although compliance with these standards is not mandatory, innumerable local and industry-specific organizations strongly recommend compliance with certain ISO standards. This particularly applies to ISO17025, – the most important standard governing testing and calibration laboratories and thereby also pertinent for measuring instruments like scales.

There are standards of protection in place for all types of electrical products, e.g., IP and NEMA, including a standard for the protection of electrical production equipment against dust penetration and the protection of equipment used in cleaning processes. A neutral testing laboratory conducts product certifications. In this process, the vendor is also required to furnish a declaration of conformity, although certification is not mandatory.

In Europe and other countries, OIML or CE rules and regulations apply. Scales that satisfy these rules are approved for use in legal metrology. In the USA, the NTEP (National Type Evaluation Program) declaration of conformity is issued by the National Conference on Weights and Measures (NCWM). It evaluates the performance, operation, and compliance of weighing and measuring instruments based on established criteria. Even though such approval is not mandatory, a U.S.-recognized certificate of conformity is issued after the procedure has been completed successfully.

All of the CE, UL, ETL, CUL and CSA standards provide guidance on product safety, especially that pertaining to electrical production equipment. The Underwriters Laboratories Inc. (UL) is an organization that evaluates products according to accepted safety standards like the National Electrical Code (NEC) and awards a UL or CUL (Canadian) trademark for products that meet or even exceed the criteria. CSA International is the body that tests and certifies a wide variety of product types for applications in the USA and Canada.

For the pharmaceutical and healthcare products industry, it is the United States Pharmacopeia (USP) that is responsible for setting quality standards. The most important standard for the weighing industry is found in USP Section 41 which deals with testing of weighing instruments at their site of installation. Certified weights are used for the testing to determine whether the scale in question is functioning properly in its specific environment. Also known as the uncertainty of measurement test, this procedure can additionally establish the smallest sample quantity that can be weighed on a particular scale.

Setup, Installation and Startup

As part of the installation process, the room in which the scale is to be used should be set up in such a way as to minimize effects from humidity, corrosion, vibrations and electrostatic influences. These factors can all negatively impact a scale’s performance. After unpacking the scale and checking that the delivery is complete, the scale is set up at its final location and connected to any accessory devices. On many scales, the display and control unit can be set up at a remote location as a means of protection against potential hazards or for reasons of operator convenience.

The resolution readability should be set and the initial calibration carried out to enable the scale to function as intended. A corner load test should be conducted whenever multiple load cells are being used; this will ensure that the identical weights are measured in all corners and corner load errors are prevented.

The operating programs in electronic scales feature options to adapt the scale to its place of installation (e.g. to set a higher weighing time in unstable environments in order to keep the readout more stable).

To ensure that a scale produces optimal performance, a scale should not be moved from its place of installation after initial installation. The reason for this is that external variables like a very uneven floor can affect performance. Re-installation is not required on scales that are equipped with wheels to make cleaning easier as long as the scale is returned to its original location after cleaning and prior to further use. If a scale has to be re-installed at a new location, the installation procedure must be repeated. Normally, the end user can perform the installation. However, if traceability and documentation are important concerns, then it is recommended that the installation be performed by an authorized technician so as to ensure proper installation and calibration documentation.

Scale Calibration and Service

Scales are made of electronics and moving parts which are constantly exposed to stress. With time, this wear and tear can cause the accuracy of the scale to shift. In turn, these changes can affect the overall weighing results and cause problems, especially for scales with higher resolutions. For these reasons, every scale must be calibrated regularly. Without regular calibration, consistently accurate and verifiable results cannot be ensured.

The process of calibration measures the weighing accuracy of a scale or load sensor. Ideally, calibration is performed at the place of use of the weighing instrument. This will avoid the quality problems that can arise at every step of the manufacturing process whenever weighing results are out of specification. During a calibration routine, a series of certified test weights are placed, one after another, on the weighing platform and the measured results are noted down. Special procedures apply to load cells attached to large vessels or tanks where extremely heavy weights can be involved. To correct any out-of tolerance results, manual or automatic corrections can be made whenever the displayed results deviate from the known test weight. This correction procedure is called adjustment. The operator can carry out this test as part of the routine accuracy testing. However, the certification itself may only be performed by trained and authorized technicians using certified and verifiable test weights. This approval or certification is issued according to a specific set of standards like NTEP or ISO 17025, for example. Depending on the ambient conditions, frequency of use and company-internal regulations, the instruments should be calibrated regularly. As a guideline, common practice dictates that calibrations are performed four times a year. In certain cases, daily calibration may even make sense and indeed is carried out in critical sectors like in the pharmaceutical industry.

When setting up a scale, one should also adapt it to the ambient conditions, if necessary.

A calibration certificate issued by the German Calibration Service (DKD) is the most reliable way to effectively prove a scale’s metrological qualification at the point of use. Such certificates can only be issued by accredited testing laboratories (as a general rule, by the scale manufacturer as well), after solidly demonstrating their capabilities and reliability. Hereby, testing must be carried out using test weights of prescribed accuracy classes guaranteed to be traceable to the kg standard. The customer service of the manufacturer or an authorized representative must be called upon whenever the scale or load cell is outside of acceptable calibration limits or a more serious problem occurs. If the customer performs repair work themselves, this will often make any product warranties or service contracts invalid. Service contracts can be customtailored to the individual customer’s needs and often cover regular calibration as well. Moreover, service contracts can also provide for prompt emergency repairs to shorten downtimes.

Influencing factors when determining price

Of course, no discussion of the evaluation of a scale is really complete without price also being addressed. Only once a scale has been selected paying heed to the previous criteria can a benefit assessment then follow. It is clear that limitations on quality need to be accepted for a ‘cheaply’ manufactured scale. This kind of scale would not provide benefits so well (in terms of quality) and for so long (life cycle cost). Replacements or repairs can very quickly have a negative impact on total cost balance. If interruptions to the process or reworking are associated with this scale, it may become expensive.

Having said that, it’s not necessarily the case that the most expensive scale is always the best. Carefully and objectively weighing up the factors in conjunction with current and future weighing requirements as well as the total cost calculation should narrow down the selection to the scale that’s just right in the end. Attached is a check list to help the user select the right scale.

Checklist for the selection of the right scale

Industries that benefit from implementing the Flat Bed IF Series, case studies

Ensuring precision and quality for a versatile dosing station with two weighing points Download Here →

Minebea Intec’s products support the creation of a vaccine against Corona Download Here →