Home of alluring art, incredible history, heavenly food, stunning landscapes and phenomenal fashion, Italy epitomizes life in all its lazy, elegant brilliance. Italy is ‘La Dolce Vita’ – “the sweet life” – a life of heedless pleasure and luxury.

This story is a surprising marriage of two Italian things that best symbolize heedless pleasure and luxury – supercars and gelato. This is a story of how a small Italian company, well-known for their expertise in super car Internal Combustion (IC) engines, helped an ice-cream manufacturer make better gelato.

Made in Modena, Italy

Our story starts in Modena, the ‘City of Engines’. This charming Italian town is also the unofficial ‘supercar capital of the world’. Ferrari, Lamborghini, Maserati, Pagani and Bugatti all call Modena home.

Modena, Emilia Romagna, Italy. Piazza Grande and Duomo Cathedral at sunset.

It is here, that Giuseppe Calise, a graduate of the nearby University of Modena and Reggio Emilia, established R&D CFD in 2012 with his Professor, Dr. Stefano Fontanesi. Borne out of the University’s Internal Combustion Engines (ICE) research group, they do engines well. Really well.

The CFD in their name is a nod to their expertise in computational fluid dynamics (CFD) simulations. R&D CFD works with most of the supercar manufacturers around Modena helping them build better IC engines digitally using CFD simulation.

IC engine operation is complex. Combustion of air and fuel, temperatures of 4500 F (2500 C), moving pistons, hundreds of chemical species, and thousands of reactions some of which occur in a billionth of a second. All of this inside a small, dark cylinder, inside a fast supercar.

How do you analyze such complexity? How do you find the best engine design?

With CFD, companies like R&D CFD build a digital engine. Every process in and outside the engine is digitally modeled, analyzed and visualized. Add in design optimization and you can evaluate hundreds of scenarios and designs digitally before building anything.

In 2019, their CFD simulation and engineering expertise caught the eye of an unlikely customer: a leading Italian gelato manufacturer.

Simcenter STAR-CCM+ simulation showing thermal behavior of engine components, courtesy R&D CFD

The variegated gelato

The global ice-cream market is worth $80 billion USD and increasing every year. Nearly 80% of the ice-cream sold is machine-made, either to take home in a box or consume immediately. It’s a massive market.

The manufacturer who worked with R&D CFD is famous for their variegated gelato. Excuse the fancy word here! A variegated gelato is merely ice-cream with a sauce swirled into it – chocolate, strawberry, caramel, fruit, peanut butter and more.

Chasing the good (looking) gelato

Ice-cream was once a dessert for kings. But thanks to capitalism and mass production, the common man can enjoy one of life’s greatest delicacies. Our gelato maker was one such mass producer. Gelato in a box was their specialty. With years of mass-producing experience, the taste of their gelato was world class – creamy, rich and dense.

Good gelato needs to be good-looking. No one likes a dull, rough, garish looking ice cream. Eating ice-cream is an emotional, evocative experience. In a competitive market, the look and feel of your gelato makes all the difference. The manufacturer’s list of requirements for aesthetically pleasing variegated gelato was long: soft, smooth, silky, elastic, and of natural colour. Improving the look will have a direct impact on sales and customer satisfaction.

“The customer wanted our help to predict how their variegated ice-cream would look at the end of their manufacturing process. People who buy this ice-cream are looking for a certain hand-made feeling. But how do you make it look hand-made in a machine?”

A simpler design; a better swirl

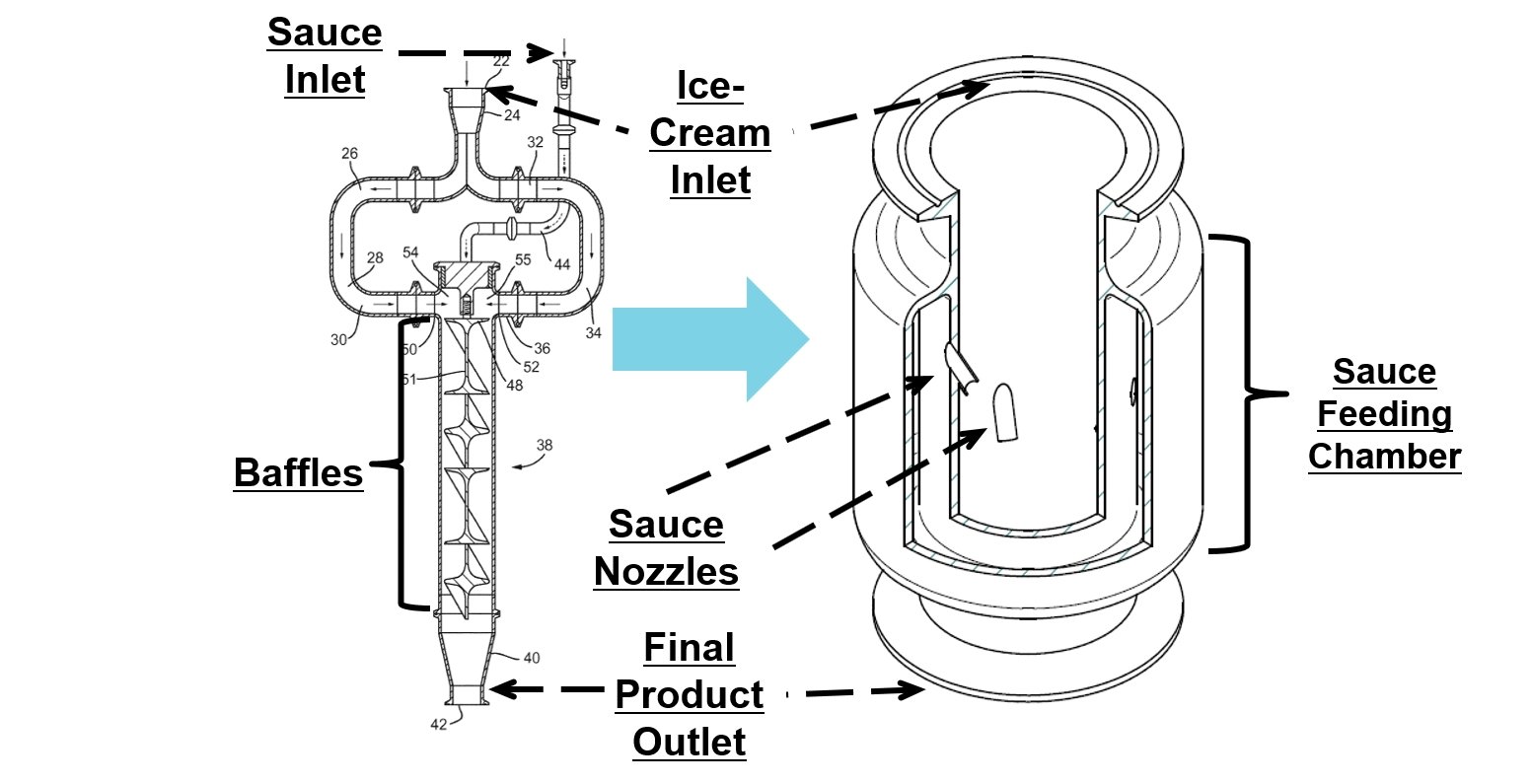

The secret lies in the variegator. This machine mixes the ice-cream and the sauce, fed through different pipes. Their current variegator was a static one with no moving parts. But the design was complex. The ice cream and sauce came in contact with screws, baffles and walls. It was hard to control the sauce pattern or mixing. It was exposed to air, a strict no-no for good gelato. The number of parts meant cleaning the variegator thoroughly was difficult to do.

The ice-cream maker found a simpler design. Just two concentric cylinders, one each for the ice-cream and sauce and a nozzle connecting the two. They mix directly in the variegator: no screws; no baffles; or interaction with walls. Just simple, straight mixing. Easy to clean, better to control mixing and a more beautiful sauce swirl into the ice-cream. In theory, the new design was perfect.

Good variegation

Improving the variegator with CFD simulation

Now they needed to make the design better. They needed to predict how the ice-cream would look after manufacturing before being stored in boxes.

This is where R&D CFD’s simulation and design optimization experience came in handy. They had Simcenter STAR-CCM+, a CFD Multiphysics software and Simcenter HEEDS, a design optimization software, both tools from Siemens’ Simcenter portfolio. For years, they used Simcenter STAR-CCM+ on supercar engines to understand the flow and thermal behavior of engines. Simcenter HEEDS helped them analyze the performance of hundreds of designs and scenarios.

Poor variegation

The simulation technology used to design supercar engines was now being applied to gelato making.

“We decided to use our engine simulation tools to improve the variegator design. With digital simulation, we could reduce making prototypes and save time and cost in design. It also helps us analyze hundreds of designs”

2,000 designs; one perfect sauce swirl

“Simulating ice cream and sauce is not so simple as simulating air and water. They are gooey, viscous, elastic fluids. Understanding the rheology and thermal behavior took some time”

Simulating these visco-elastic fluids with CFD is challenging. With Simcenter, they could model such challenging physics, thanks to a Volume of Fluid (VOF) multiphase and rheology model. The software was able to model the ice-cream, sauce, and the interface between the two accurately.

“In the past, we worked with other simulation software where the process was way more difficult. What we enjoy with Simcenter STAR-CCM+ is the variety of physics you can simulate, from engines to ice-creams”

Using Design Manager, a technology within Simcenter, Alfonsina modeled 2,000 different design scenarios changing the nozzle geometry and operational physics laws to inject sauce. The software automatically found the design that produced the best sauce pattern and swirl.

Imagine having to build and test 2,000 different variegators instead!

80 designs; best variegation

For mass production, the variegator needed multiple nozzles for faster operation. All these nozzles need to be fed the same quantity of sauce from the feeding chamber. This way, the ice cream in every box was identical in appearance and texture, ensuring customer satisfaction.

Alfonsina used Simcenter to automatically analyze different geometries of the sauce feeding chamber and the resulting sauce distribution. After analyzing 80 designs, the best feeding chamber design was found. Now all the nozzles receive the same amount of sauce. Mass production of perfect gelato activated!

Different nozzle designs to find the design giving the best sauce pattern and swirl

“It’s so fast to do automation and optimization with Simcenter HEEDS or Design Manager”

You can see how the optimized design gives the same, beautiful swirl to the sauce from every nozzle compared to irregular patterns from the initial design.

Baseline Design showing poor variegation and irregular sauce pattern from four nozzles

Optimized Feeding Chamber Design giving similar swirl pattern and better variegation from all nozzles.

From ICE to ice-creams

R&D CFD’s improved variegator design is now in use in all the manufacturing plants of the customer. As predicted with simulation, the variegation is top-notch.

The team at R&D CFD experienced something unique – eat something they helped engineer.

“I’ve tried the ice-cream and I’m very appreciative of the job done. Looks delicious. Tastes delicious”

“We live and breathe internal combustion engines (ICE). We never thought we’d be working on making better gelato. With Simcenter, we have gone from ICE to ice creams”

Beautiful swirl pattern of sauce from CFD simulations was replicated in the new variegators built by the manufacturer.

How can we help you?

Interested in our engineering and consultancy services? Send us your inquiry via the Engineering and Consultancy Services Form and we will be pleased to help you.