How can automakers benefits from simulation software to create a safe autonomous vehicle/electric vehicle

Optimizing coverage and reducing validation costs in the ADAS and AV development process

As vehicles become more automated with advanced driver assistance systems (ADAS), development and validation testing conditions need to be defined. Which scenarios should be considered for ADAS and future autonomous vehicles (AVs)? How can a large number of potential driving situations be considered and how can the most critical ones be identified? Can verification and validation (V&V) be managed in a realistic timeframe and at an acceptable cost?

This blog post highlights a process applied during vehicle development, and discusses the support Siemens Digital Industries Software and ETS Solutions Asia engineering services team can provide.

When designing mechatronic systems, it is critical to define proper test cases for their development and validation. Test cases derive from an analysis of Vehicle-level and System-level requirements and functional safety standards such as International Organization of Standardization (ISO) 26262 and ISO21448. This analysis helps define fault-mode test cases, which consider the failure of subsystems and components. Model-based design (MBD) is a framework that uses test cases to verify the system throughout the development process. Test cases are consistently linked with requirements and to the vehicle models and control algorithms. These are regularly updated as the system is defined and used to develop and validate the system.

Requirements and safety-based test cases

This development process has been applied in applications such as automotive transmissions and ADAS. It is increasingly difficult to identify all potential scenarios for ADAS and AV features being developed.

ISO26262 defines functional safety requirements for automotive electric/electronic systems. It addresses potential hazards caused by malfunctioning systems in automobiles. However, this is not sufficient for AVs since hazards can still occur while their systems are working without component failures. Safety of the intended functionality (SOTIF) has been introduced to deal with these situations.

In order to increase the coverage of scenarios for both ADAS and AV applications, Simcenter™ Engineering and Consulting services, which is a part of the Xcelerator™ portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, uses SOTIF-based system theoretical process analysis (STPA) to support the hazard analysis. STPA addresses external and internal events and process control actions that could result in unsafe conditions. The STPA methodology derives technical safety requirements and identifies test cases in an improved way. The iterative and recursive test-case generation process requires scenarios to be modified throughout the system’s development.

Defining the required scenarios for ADAS and AVs is a topic of interest for original equipment manufacturers (OEMs) and suppliers.

The purpose is to provide broad coverage for instances that may occur while using the vehicle and to identify critical, unsafe scenarios. Different sources can be used to identify relevant scenarios for system development and V&V. This includes existing standards, public literature, real-driving data, etc. Also, accident databases like the German In-Depth Accident Study (GIDAS) and China In-Depth Accident Study (CIDAS) contain useful descriptions of accidents.

Although safety is the main element in defining validation scenarios, comfort aspects of ADAS features should be analyzed as well.

Comfort can include vibration levels, driving dynamic performance, driving style, and perceived safety. Simcenter Engineering is developing methods to identify relevant scenarios, comfort metrics and control algorithms that combine safety constraints with comfort requirements.

Test scenarios based on real-world driving

To identify real-life scenarios, the vehicle is tested on a public road with suitable instrumentation. Many automotive companies have been recording large amounts of data on roads with different traffic and weather conditions. Today, there is access to a significant amount of proprietary and open-source data. Identifying a larger set of potential scenarios is necessary to expand coverage, starting from real-world driving data.

Simcenter Engineering supports testing and data processing with activities such as:

Test campaign definition – captures the required driving conditions

Vehicle test setup and sensor configuration – defines requirements to accurately identify driving scenes

Data acquisition system – captures object data and/or raw sensor data

Sensor calibration –corrects sensor output for further processing

Perception algorithms – identify lanes, traffic signs, vehicles, and other entities

Scenario description – defines scenes in OpenSCENARIO format

Scenario mining – performs statistical analysis of the scenarios and traffic conditions

Once scenarios are identified, they can be imported into simulation models to front-load the development.

Virtual development framework

Assessing system performance early in the design enables front-loading development. A large number of realistic conditions need to be assessed in an integrated fashion according to the principles of MBD.

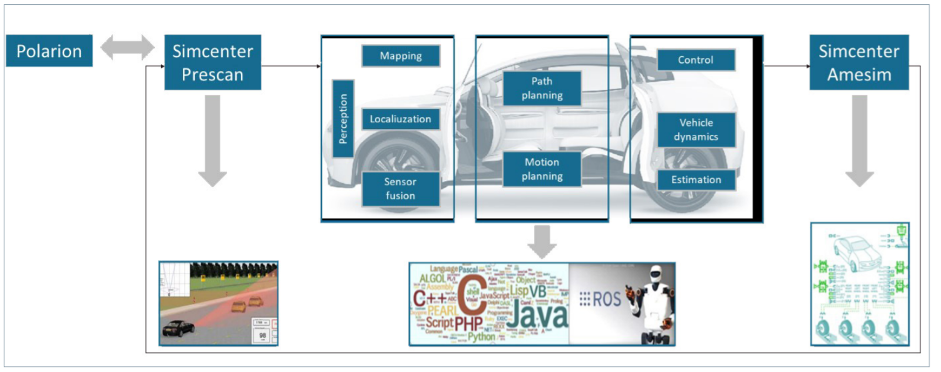

System evaluation is supported by dedicated simulation tools such as Simcenter™ software. Using Simcenter Prescan™ software enables simulation of the driving scene, including static elements (roads, road signs, traffic lights, etc.), dynamic elements (other vehicles, pedestrians, etc.), the environment (rain, fog, shadows, etc.), and sensor models (cameras, lidar and radar).

Simcenter Amesim™ software is used to simulate vehicle dynamics. It is coupled with Simcenter Prescan, which allows the user to predict how the vehicle will respond in the given scenarios. Optimization solutions such as HEEDS™ software are used to screen the system’s performance with multiple scenarios and support design optimization. An application lifecycle management (ALM) tool such as Polarion™ software is used to define and track system requirements for hazard analysis, failure mode and effects analysis (FMEA) and managing control software and test cases during development.

Simcenter Engineering supports the setup of a development framework according to automotive OEMs and suppliers needs. Different software tools are integrated as needed, baseline algorithms and scenarios are provided and sensor models are created, validated and parameterized. Vehicle dynamic models can be created from templates or based on full-vehicle testing and reverse engineering.

Quantitative and qualitative scenario expansion

Initial scenarios obtained from the sources mentioned above can be expanded to represent a larger amount of conditions expected during the vehicle’s life.

This is illustrated by the SOTIF-based four-quadrant diagram. Simulation is used to minimize the amount of unknown, unsafe scenarios. The virtual framework is used to screen the scenario space using representations of the environment and traffic scenes in combination with design exploration. Dedicated algorithms based on artificial intelligence (AI) and adaptive sampling are used to generate new and critical scenarios. The adaptive sampling method identifies these relevant, critical scenarios while minimizing the amount of experiments.

In order to explore the scenario space around a specific event, Simcenter Prescan can also be connected to traffic simulation software that is used to generate realistic traffic flows.

Reducing validation time and costs

Simulation is used to front-load ADAS and AV development and it reduces time needed for the V&V phase.

When control algorithms are defined, software code is generated and tested with X-in-the-loop (XiL) methods to make sure the quality of the software controls and the performance of the system is sufficient prior to hardware integration.

Before prototype testing, real-time simulators are used to verify the physical systems as they become available. For instance, hardware-in-the-loop (HiL) is used to test the physical advanced driving control unit (ADCU) connected to the virtual vehicle and system simulation models. Dynamic simulators (for example, hexapod platforms) with embedded real-time vehicle dynamics models are used to assess driver comfort or experience.

A major benefit of using virtual models is to reduce the testing effort and make verification less time-consuming and expensive.

A large number of scenarios are evaluated using virtual models, which lead to the critical scenarios being used in physical system V&V. This creates a manageable physical testing program.

Mixed-reality testing

Combining test and simulation provides a mixed-reality environment.

The integration of the virtual framework in a suitable middleware enables the user to seamlessly exchange physical and virtual parts.

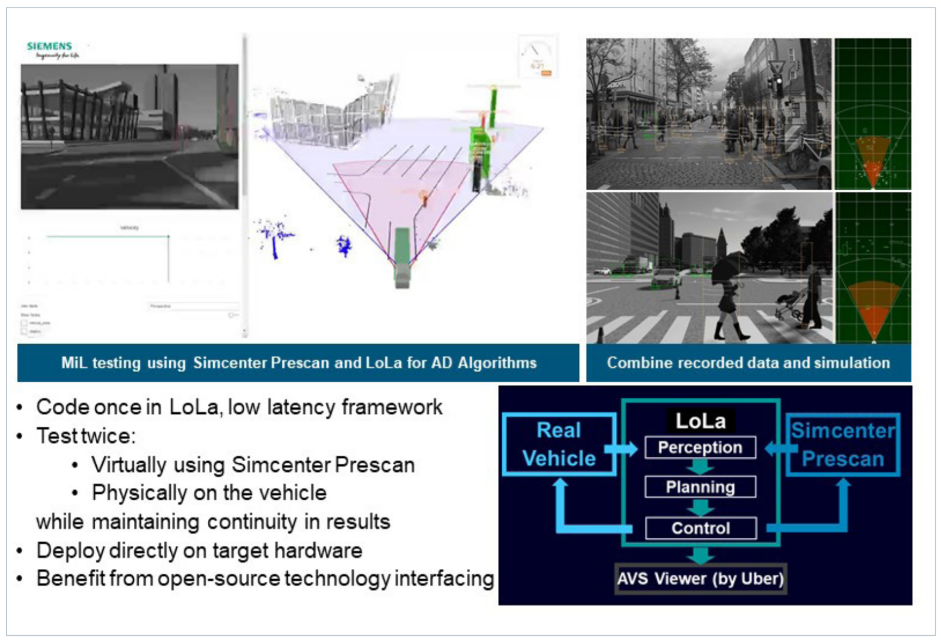

In the example below, the autonomous driving stack is tested in the virtual world, then seamlessly deployed on target hardware using low latency (LoLa) middleware.

Eventually this leads to a vehicle-in-the-loop (ViL) setup. This uses the real vehicle on a test track and introduces virtual elements such as static and dynamic vehicles or obstacles from the virtual framework. The vehicle sensors detect the virtual actors as if they are physically present. This provides greater flexibility in setting up test scenarios and reduces time, cost and risk when performing unsafe manoeuvres.

Vehicle testing on proving ground can be supported by the Siemens ADAS testing team, which can perform various types of homologation testing, such as the New Car Assessment Programme (NCAP), and help customers with their testing challenges.

Using simulation helps define which test cases to consider for system V&V while front-loading system development. Siemens products and ETS services optimize the development process and support OEMs and suppliers to develop and validate their systems in a reduced amount of time and cost.

How can we help you?

Interested in our engineering and consultancy services? Send us your inquiry via the Engineering and Consultancy Services Form and we will be pleased to help you.