The customer is a world-leading technology company. It researches and develops solutions for safety, environmental protection and networking, in order to keep developing mobility in a sustainable way. The injection moulding company currently employs 147,000 people and operates 14 technical centres as well as production locations and customer service centres across 45 countries.

How Minebea Intec Combined Precise Weighing Results with a Flexible and Mobile Design

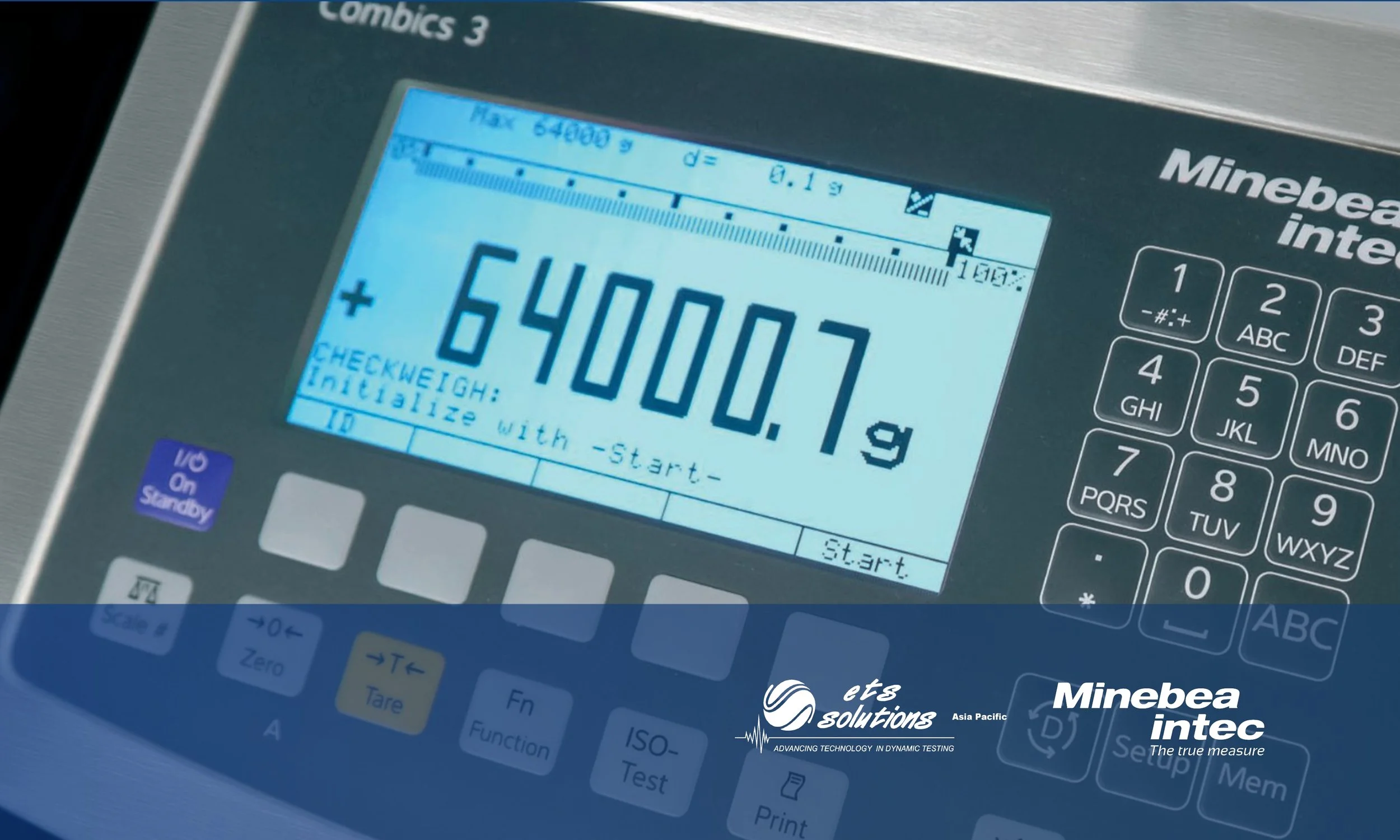

Mobile scales excel in industrial environments in which work processes require greater flexibility and better use of space. A high-resolution industrial scale was combined with an indicator to create a flexible and precise weighing solution. A high-resolution platform for precise results was combined with an indicator for accurate counting and weighing in a clean room. The weighing solution was combined with wheels and batteries for mobile and flexible operation.

High-speed weighing in the smallest of spaces: checkweigher exceeds all requirements

The company has been a Minebea Intec customer for many years and was already using Vistus metal detectors to check various products for metal contamination. Now, the customer needed a high-speed checkweigher that was MID approved and could deliver speeds of up to 800 products per minute. Minebea Intec met this challenge by developing a customer-specific version of the checkweigher Flexus Combi. The specially developed checkweigher is a dual-track solution, in which the two tracks support speeds of up to 400 pieces per minute.

Vistus brings better sensitivity and space-saving metal detection solution for dried and fresh fruits

Due to an increased production volume, the Pacific Nut Company Chile S.A. expanded its production and packaging lines in terms of weighing, sealing, and box packaging. In the process, also the critical point of metal detection needed improvement. The former metal detector, checking packed boxes of up to 10 kg dried raisins, had shown a lack of detection sensitivity. In addition, thermal fluctuations and changing humidity conditions had led to false rejections. Facing limited space due to the newly expanded production line the customer contacted the certified Minebea Intec Partner Antalis Abitek.

Mobile Weighing For Clean Rooms

Boehringer Ingelheim relies on UDF vessels, which are put to use under cleanroom conditions – both after ultrafiltration and before the product filling stage. The pharmaceutical company ordered a mobile weighing solution for a 50 l ultrafiltration vessel weighing 320 kg in total. The extended remit required the solution to be resistant to cleaning products, be able to withstand transportation stresses and to include the option of connecting the weighing station to the existing PLC.

High-speed check weighing: Minebea Intec technology helps to keep up the pace in the packaging line

Narrow packs of sweets with an extremely small supporting surface had to be checked for their integrity, contamination and reliably removed at high speed from the product flow where necessary. The weighing solution had to have a MID approval for high speeds. The packs are fed onto and discharged from specially-designed conveyor belts, weighed, inspected, and ejected from the product flow were necessary at a throughput of 430 pieces per minute.