H SERIES

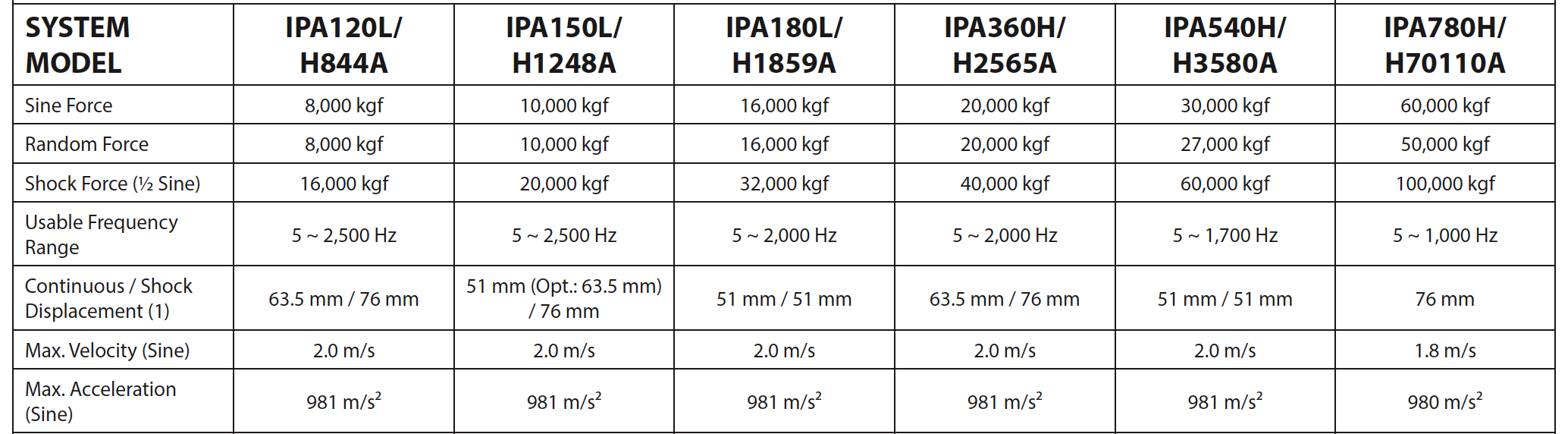

Vibration System Force Rating from 8,000 kgf to 60,000 kgf

Ideal for screening of large sized assemblies with high acceleration test requirements.

The “H” Series also meets typical vibration test requirements of other large sized electronic assemblies, automotive parts, aviation, avionics parts, satellites, aerospace and military systems.

The “H” Series vibration is designed to meet military and international test standards including MIL, ASTM, IEC, ISO, BS and JIS. A wide diameter armature with high cross-axial stiffness will allow for using a proportioned head expander to test multiple specimens simultaneously yet achieving good vibration transmissibility ratio. Other test requirements including transportation vibration simulation, combined vibration-climatic test and seismic simulations for large size components can easily be fulfilled by the “H” Series. Options are available to meet the most stringent test requirements for hazardous or explosive materials.

BENEFITS

Simple system operation

Intelligent PLC control and monitoring system

High energy conversion efficiency (greater than 90%)

Reasonably priced optimal performance system for major test standards

Compact shaker and amplifier size saving valuable floor space

Compatible with any vibration controller

Remote control panel via Ethernet cable connections

Low profile body design ready for chamber integration

Integration with unibase or standalone slip table

Shaker water cooled by water cooling system for continuous long period operation

Air cooled amplifier power electronics for safe and reliable operation

Ethernet port available for data exchange

All-encompassing fuse protection design for high current system components

Detailed scope of system interlock protections

Complies with USA, European and international safety and EMC regulations

Simple initial self-system setup

Interactive diagnostic “System Status” on touch screen

Easy maintenance and rapid servicing

Worldwide spare parts support

FEATURES

THE PERFORMANCE

Specimen payload up to 5,000 kg

Excellent random performance meeting ISO standard with 3 sigma peak current rating

Armature diameters range from 445 mm to 800 mm

Up to 63.5 mm continuous displacement

Test frequency up to 2,500 Hz

THE SHAKER

Separated water inlets and outlets current leads to the armature coil

Dual bearing shaft built-in for load support

High efficient water-cooled armature coil

Special copper flexure suspension system with high cross axial stiffness

Closed loop water cooling system

THE AMPLIFIER

Integrated with new Intelligent Power Amplifier

New design with High Speed IGBT technology

Compact sized power module with large output

High modulation switching frequency

High signal to noise ratio

Dynamic fault current error control protection

Complete digital control

THE ACCESSORIES

Dynamic and static armature centering available

Geared aided rotation built-in for uni-base slip table

Thermal barrier for combined climatic chamber test available

Remote control capabilities available